| The Peterhead whaling trade |

|

Home

|

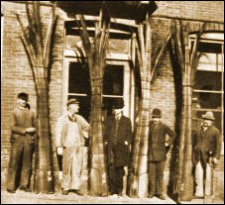

Preparing the whalebone

The baleen was generally taken from the mouth in one piece. In bowhead whales there were some 300 baleen plates on each side, the biggest up to 15 feet long and 1 foot wide. Once on board ship, the whalebone was split into pieces containing 10-12 plates and generally transported back to port without any further processing beyond the removal of pieces of gum. Back in Peterhead, the whalebone was cleaned and prepared. First of all any remaining gum tissue was removed and then the plates were submerged in water to loosen any blood and dirt. They were then taken out, piece by piece, placed on a plank and scrubbed with sand and water. Once clean they were passed to a second worker who scraped the root-end, where it had been embedded in the gum, until it was smooth. Next, a knife or shears were used to strip off the hair-like fringes on the inner edge. Finally, the whalebone was exposed to the air and sun until it was completely dry. Before it was offered for sale, it was given a final polish with brushes and hair-cloth. |